Stainless Steel Caustic Cracking

Stainless steels are more resistant to general corrosion compared with carbon steel.

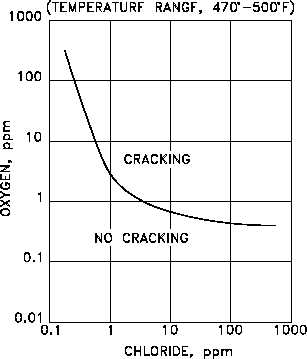

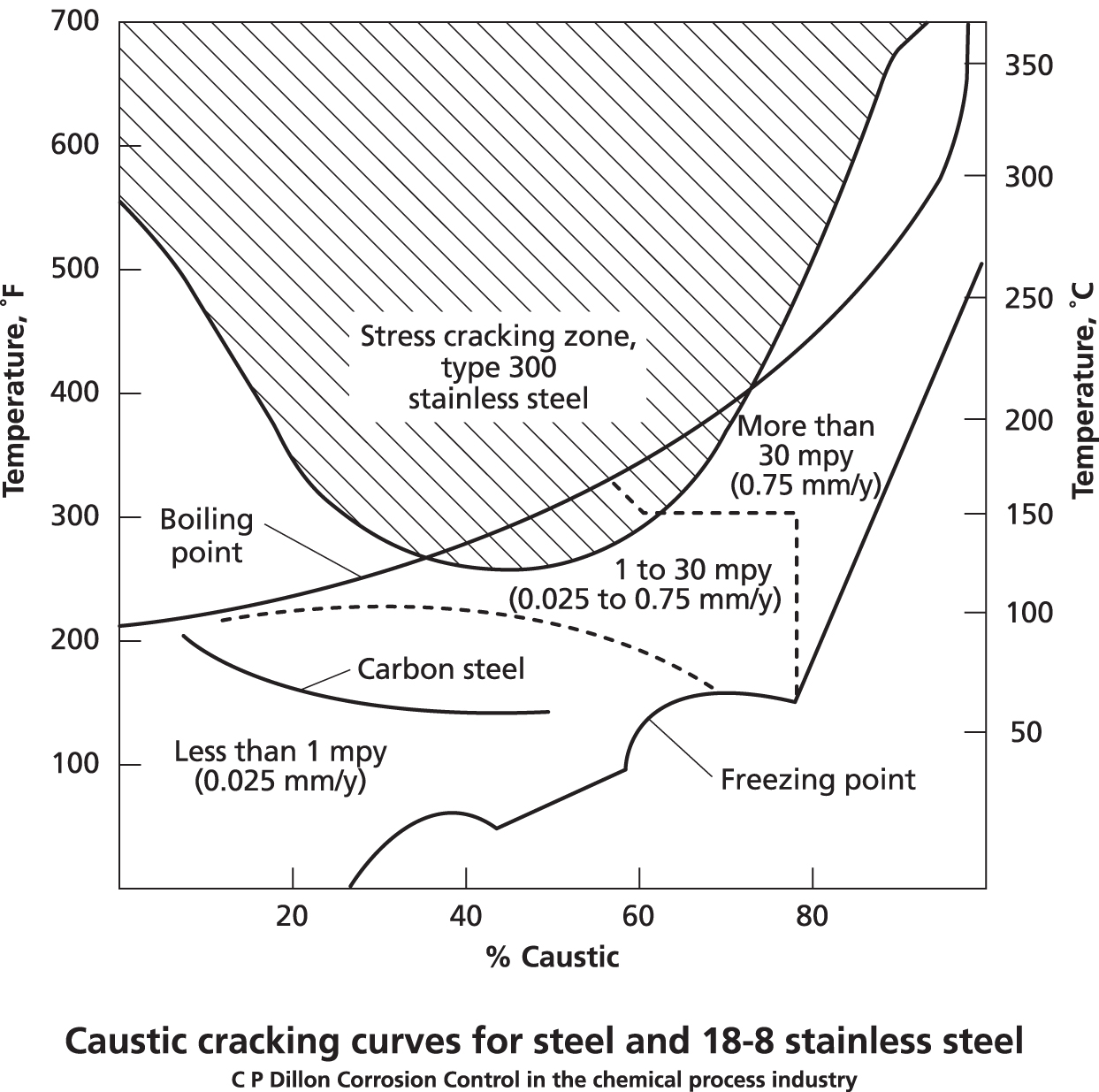

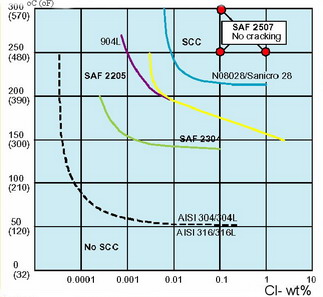

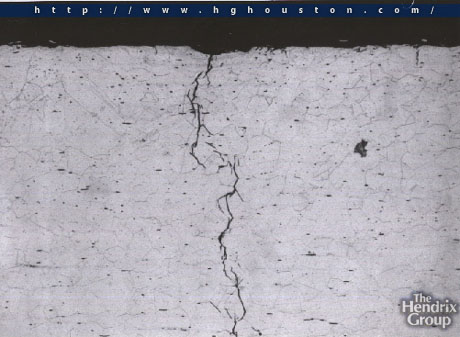

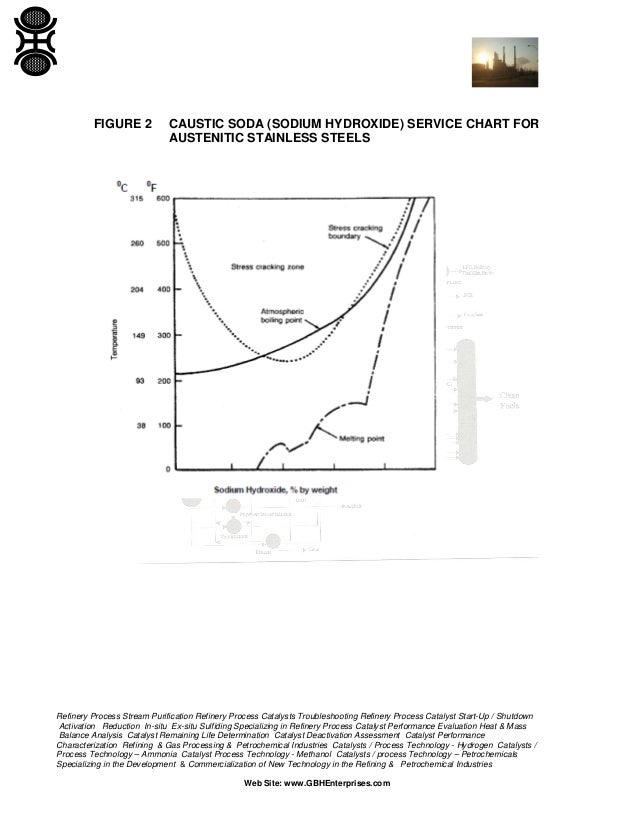

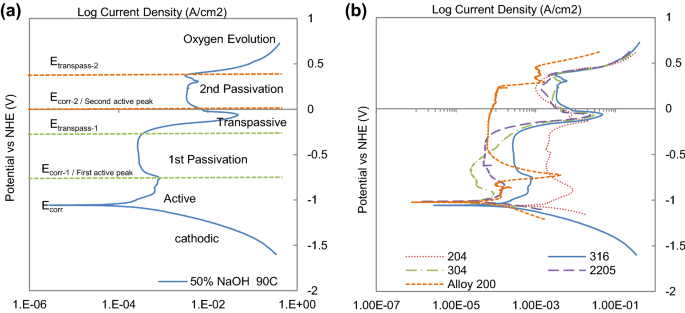

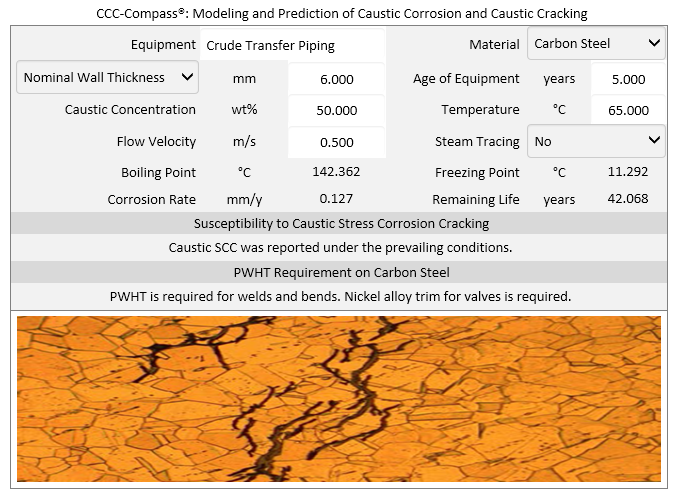

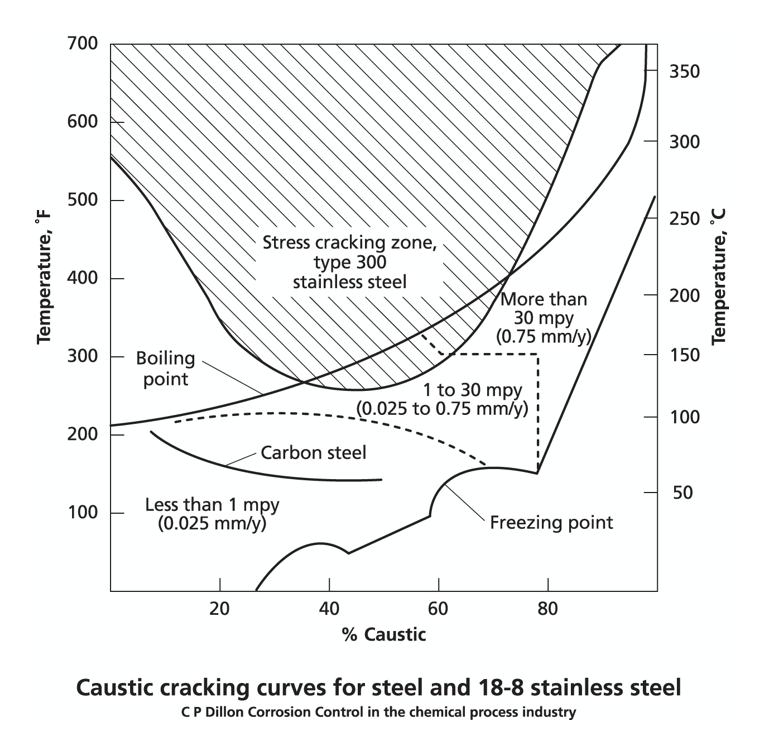

Stainless steel caustic cracking. Stainless steels types 304 and 316 can be considered resistant below 80 degc up to the limit of solubility. The useful safe limit of carbon steel is approximately 150 o f 65 o c both with regard to caustic stress corrosion cracking cscc and corrosion. Stainless steel by hot caustic research using solutions of chemically pure caustic sodium hydroxide naoh led to the development of a diagram that attempts to delineate the param eters of concentration and tem perature governing stress corrosion cracking scc of type 300 series austenitic stainless steels. Caustic cracking of stainless steels is generally tr ansgranular and caustic cracking of ni alloys is generally intergranular.

Nickel and its alloys offer excellent alkali corrosion resistance for high temperature and concentration environments. But both type of cracking can happen in both alloys. The corrosion of stainless steel in hot caustic environment has been the subject of a number of investigations typically with a focus on kraft pulping liquors 1 2 3 4 5 6 7 8 9 10 11. For example the cracking morphology of austenitic stainless steel in 50 naoh solution has nothing to do with heat treatment but is transgranular cracking.

The micrograph below x300 illustrates scc in a 316 stainless steel chemical processing piping system. However transgranular cracking may also occur. However they can suffer cscc at approximately 250 o f 121 o c. Caustic stress corrosion cracking also referred to as caustic embrittlement is a form of degradation that is caused when a component operates in a caustic environment.

The material performance in these environments is governed by the stability of the passive surface film which develops as a function of alloy microstructure chemical composition and associated environmental interactions. Caustic cracking can occur at higher temperatures. It is one of the most prevalent afflictions in the industry and one of many environmental cracking mechanisms that typically occur in carbon steel equipment but it can also afflict low alloy and austenitic stainless steel equipment. Scc in a 316 stainless steel chemical processing piping system.

It is used in metal degreasing and cleaning processes in a wide range of industry applications. Caustic cracking are generally intergranular and bifurcate. Sodium hydroxide caustic soda is a strong base. Scc of the 300 series stainless steels is classically transgranular.

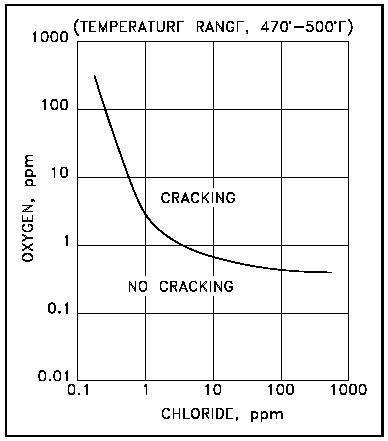

Chloride stress corrosion cracking in austenitic stainless steel is characterized by the multi branched lightning bolt transgranular crack pattern.

.gif)