Stainless Steel Mig Welding Gas Mixture

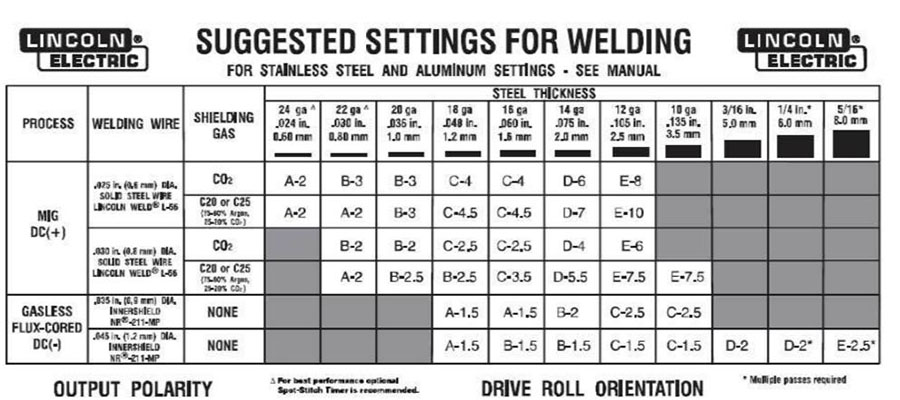

The degree of spatter is dependent upon the composition and flow rate of the shielding gas wire feed speed and the characteristics of the welding power supply.

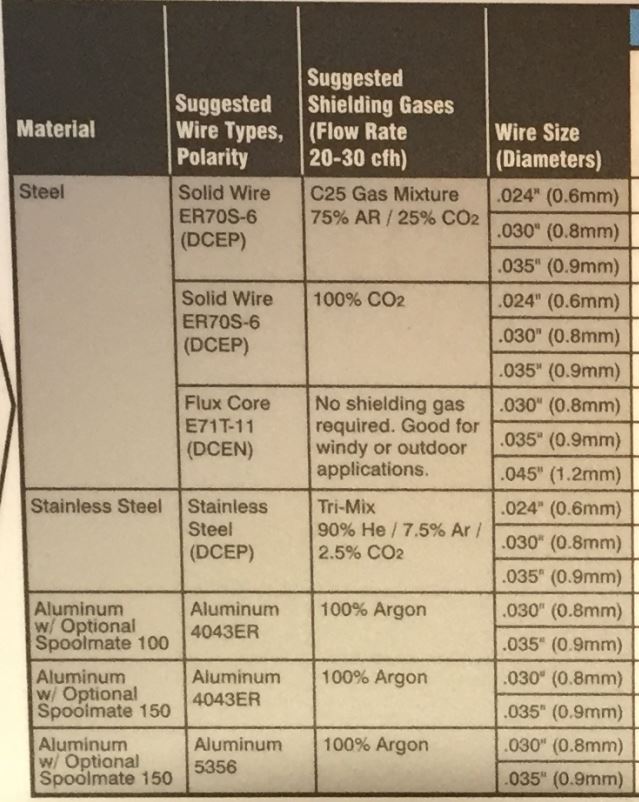

Stainless steel mig welding gas mixture. Carbon steel mig weld done with c25 gas. Mig welding gas for stainless steel welding. If your process involves welding stainless steel you need a gas with significant energy conductivity. Even though most of the welding machine manufacturers have included a table of materials and voltage settings in the machine it is highly important for you to pick the right kind of gas and electrode wire to be used for mig welding stainless steel.

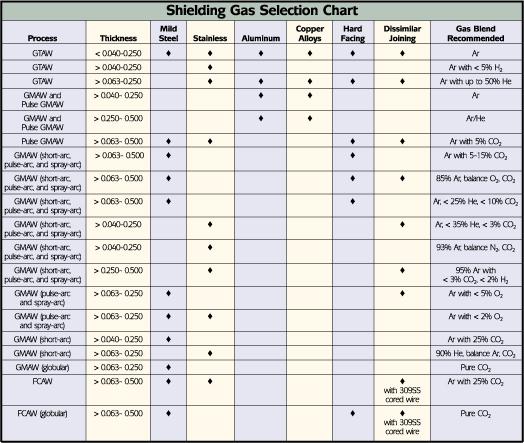

A 1or 2 argon oxygen mixture is recommended for most stainless steel spray arc welding. For most jobs welding stainless steel you ll want to use 030 inch diameter stainless steel welding wire. Welding of stainless steel is typically done with c2 or 2 carbon dioxide and 98 argon. In some cases there is tri mix shielding gas containing 90 helium 7 5 argon and 2 5 carbon dioxide.

You could also fancy a high argon gas 98 for your mig process. Gases such as high helium and argon carbon mixture are ideal. While choosing the shielding gas for mig welding stainless steel welders usually prefer a mixture consisting of argon 98 and co2 2 while some prefer to use the gas mixture of helium 90 argon 7 and co2 2. Welding of stainless steel is typically done with mixture of argon and carbon dioxide gasses that can be as low as 2 carbon dioxide to as high as 25 carbon dioxide.

For mig welding stainless steel a shielding gas mixture that s 90 percent helium 7 5 percent argon and 2 5 percent carbon dioxide is generally ideal. In some cases there is tri mix shielding gas containing 90 helium 7 5 argon and 2 5 carbon dioxide. An undercut is a small groove at the top of a weld bead that was cut into the parent metal due to inconsistent travel speed or high voltage. Alternative gases that you can use are 98 argon and 2 co2 or 98 argon and 2 oxygen mix.

Shielding gases composed purely of inert gas like argon are not well suited for mig welding steel as they frequently result in an undercut and an ugly inconsistent weld mig welding gases n d.