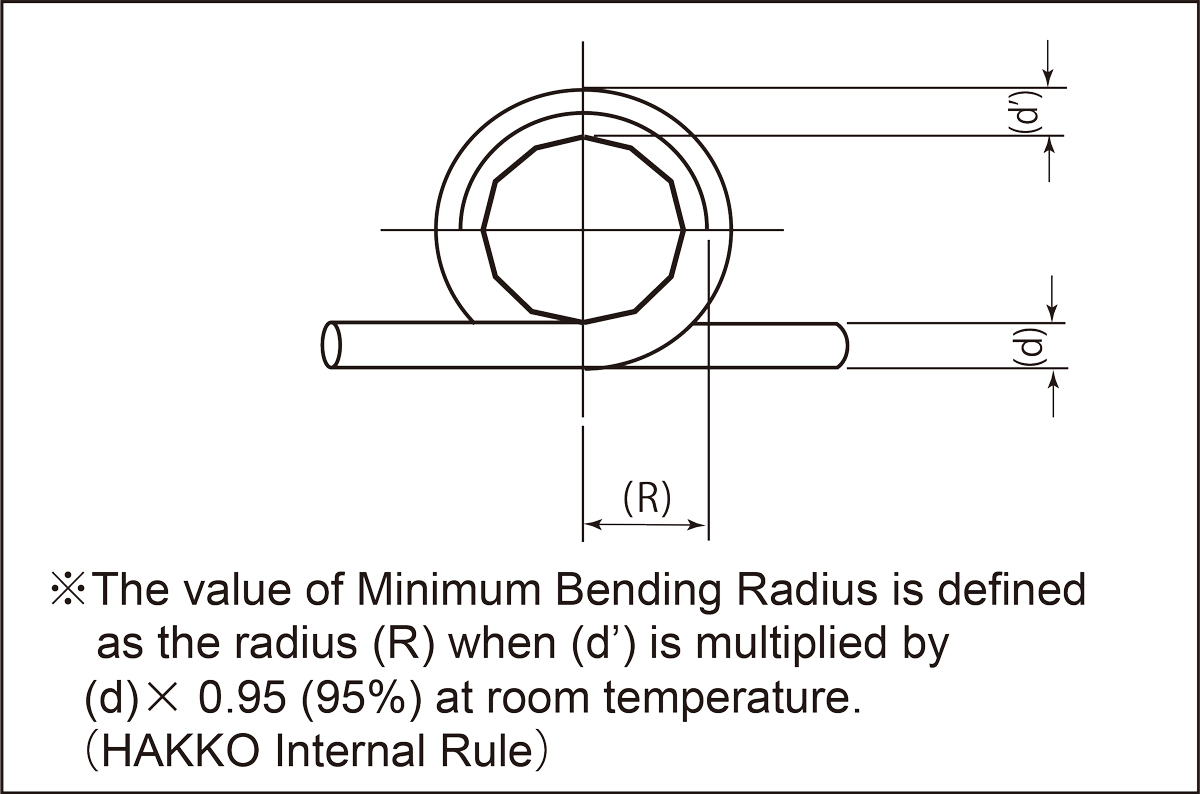

Stainless Steel Tube Minimum Bending Radius

A 2 carbon steel pipe will have a different minimum radius from a thin wall 2 aluminum tube.

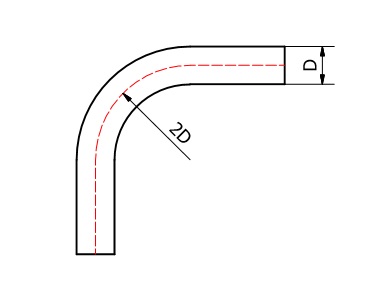

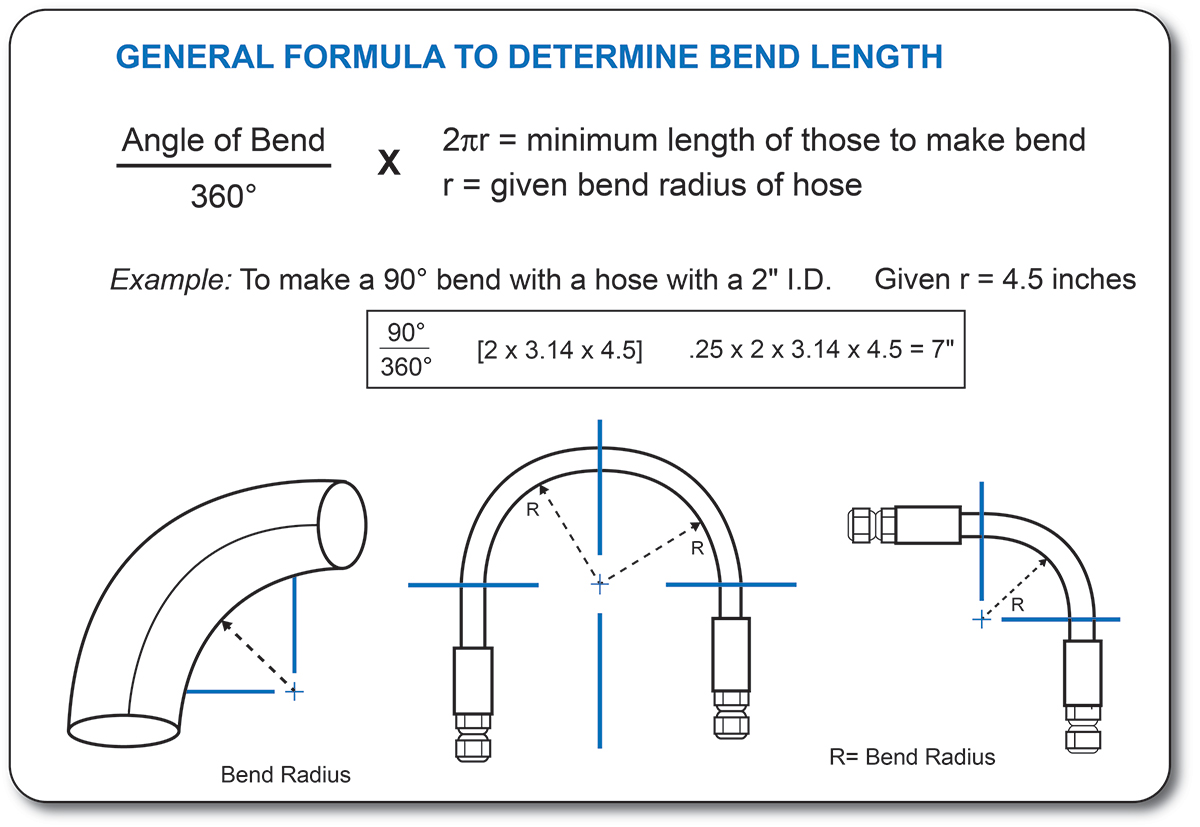

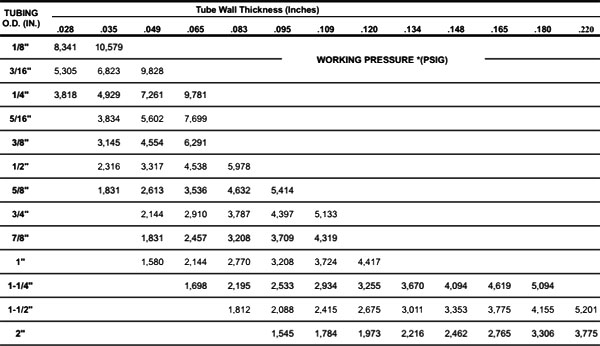

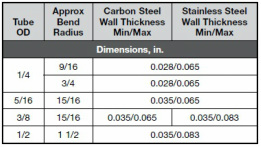

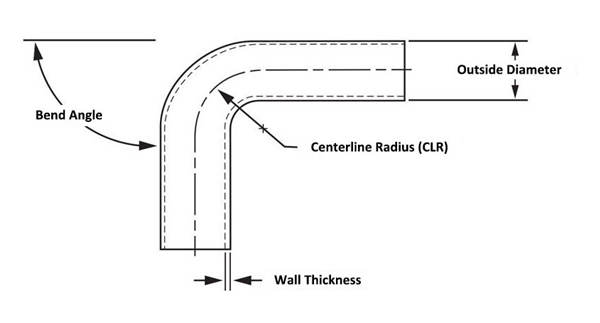

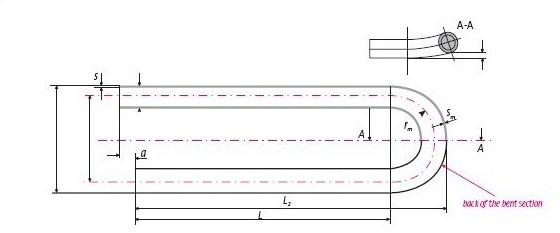

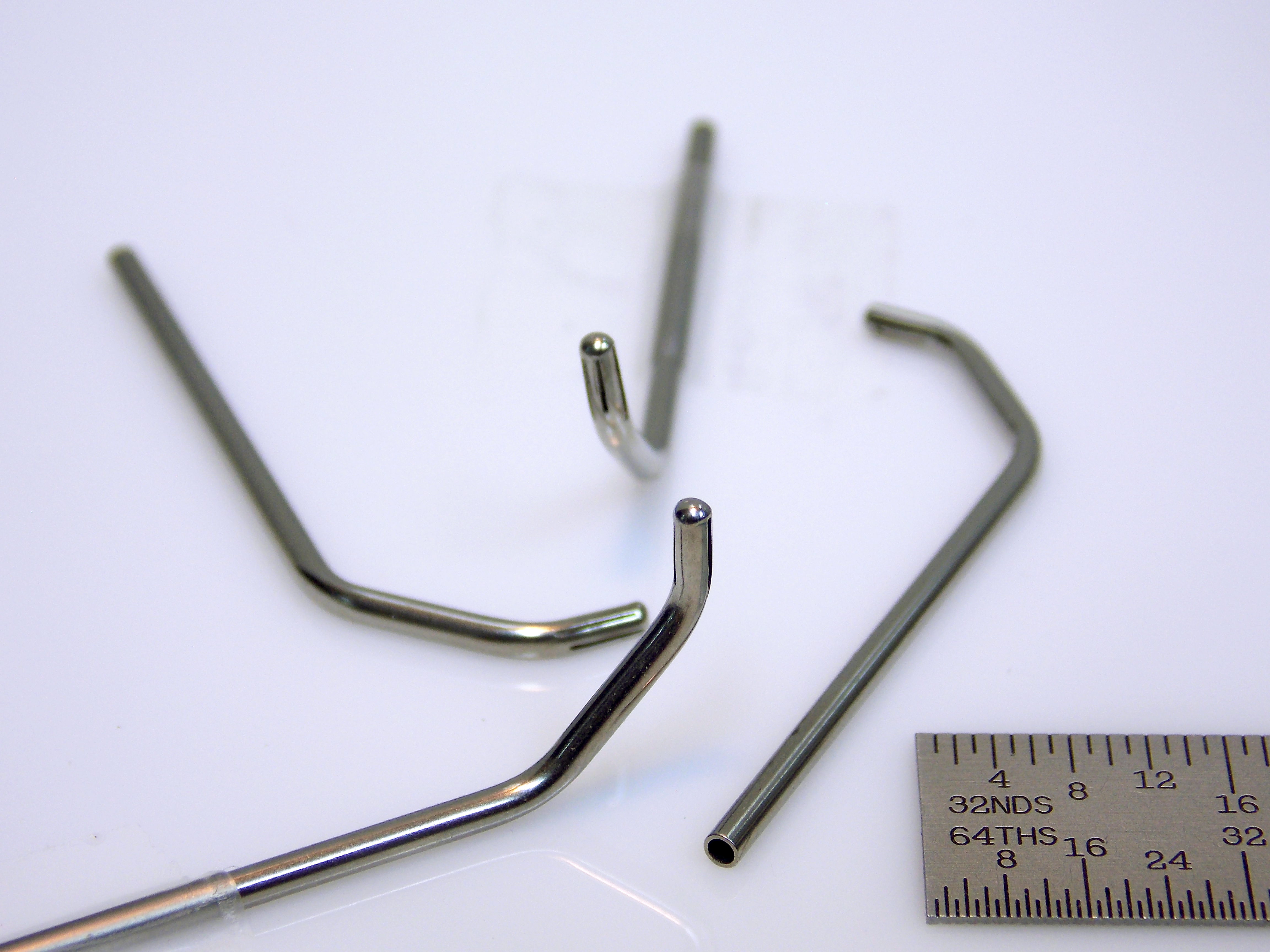

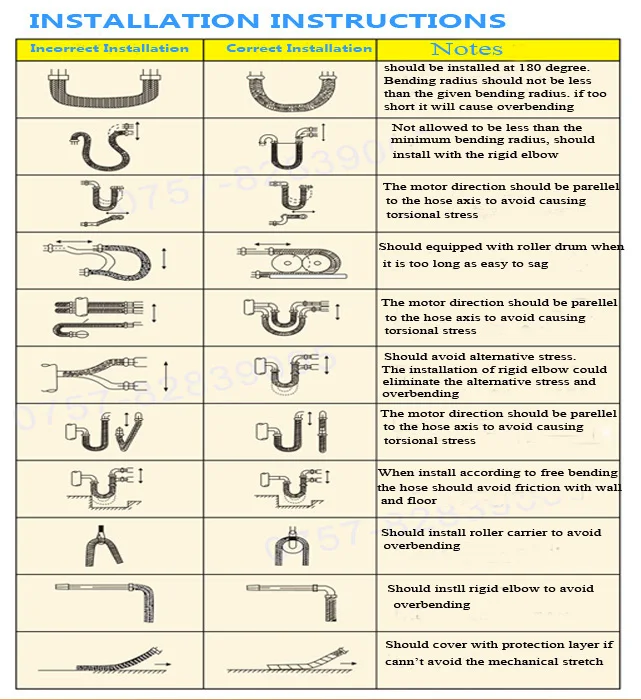

Stainless steel tube minimum bending radius. A variety of methods can be used for bending stainless steel tubing. For example on a 2 inch pipe elbow common bend measurements may be referred to as 2d 3d or 5d. The bend radius you select may not be available if the geometry of the part will not allow us to bend with the specific tooling required to achieve that radius. Use the minimum bend dimension values in the charts below for your minimum closeness of cutout to a bend.

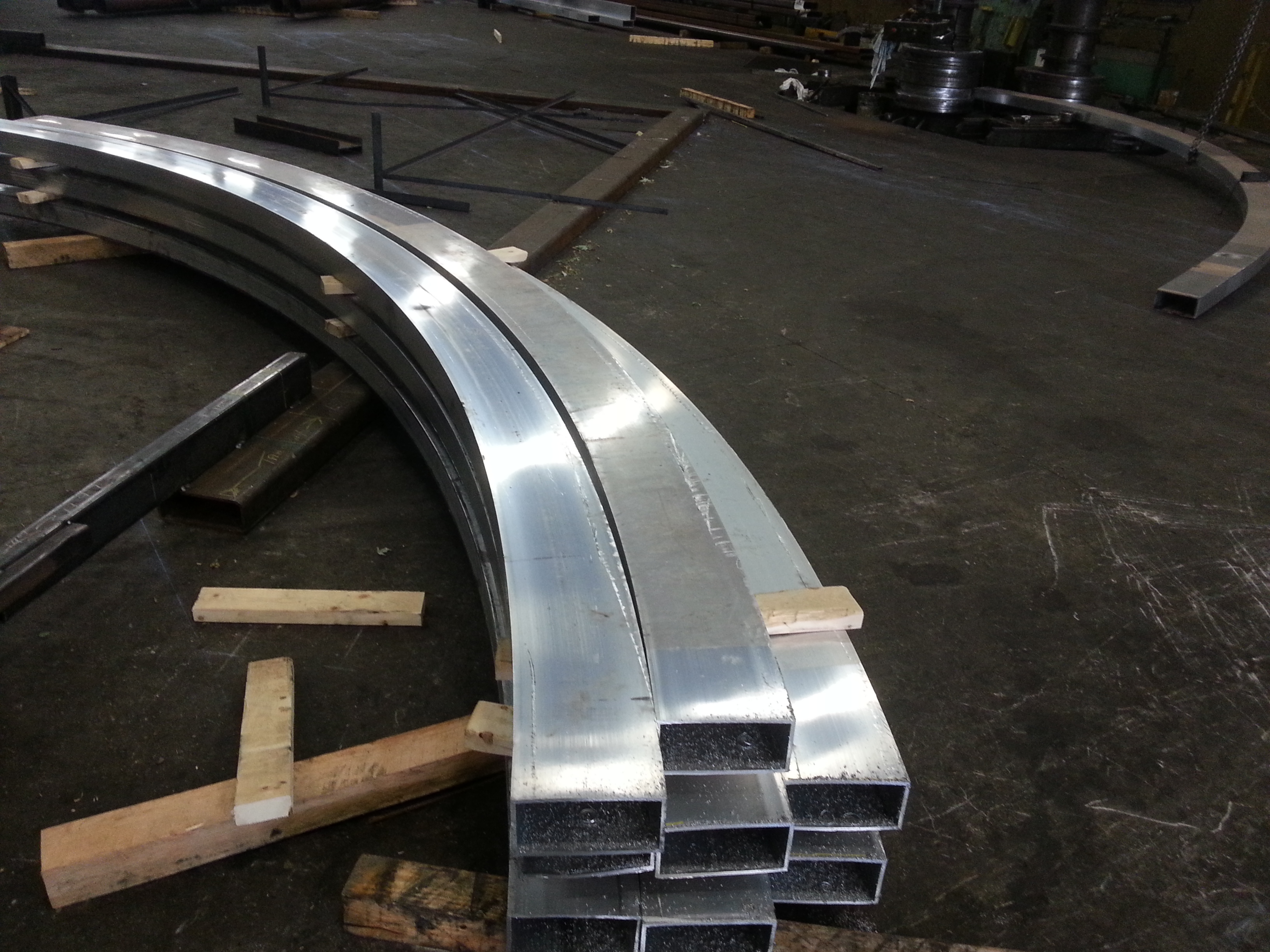

Since commercial sheet metal bending can be done with less concern for stresses caused during forming operation the radius can be near zero for thin sheet metal. The minimum bend radius data shown in these charts is measured to the inside of the bend. When we discuss tube we are of course referring to rigid metal tube or pipe normally manufactured from mild steel stainless steel aluminium or copper and normally circular in cross section although square or rectangular box section is possible and even oval shapes or more complex sections can be bent. The bend radii listed are standard minimum if manufacturing for aircraft and aerospace applications.

Material bend radii and minimum bend size charts please note. Benefits of tube bending. The minimum inside bend radius is even larger when bending with the grain. In some instances a rough guide for minimum radius bending would be to use a multiple of the piece diameter.