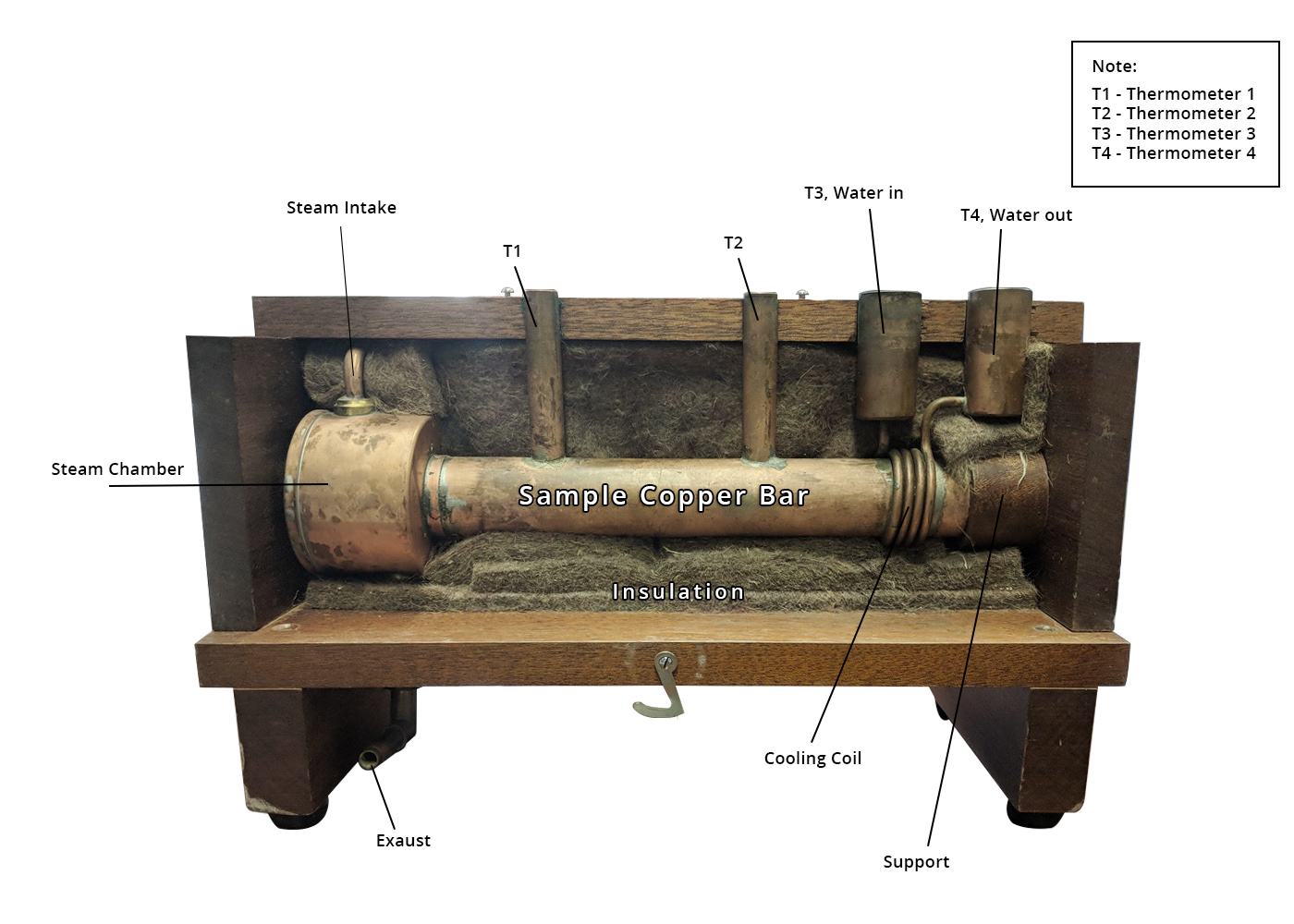

Steam To Water Heat Exchanger Experiment

Before jumping into a bunch of heat transfer projects it s a good idea to chat about the science behind these experiments.

Steam to water heat exchanger experiment. In general steam heating is used to. Maintain a product or fluid temperature. In case of plate type or shell tube type heat exchanger note the water flow rate to the heat exchanger from the digital display. Experiment regarding heat exchanger concurrent countercurrent flows at same rate and different rates.

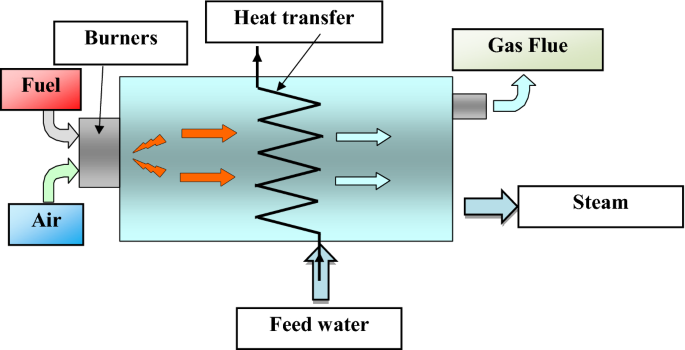

Armstrong steam to water u tube heat exchanger. A benefit with steam is the large amount of heat energy that can be transferred. Academia edu is a platform for academics to share research papers. Thermal energy is present in the molecules of an object.

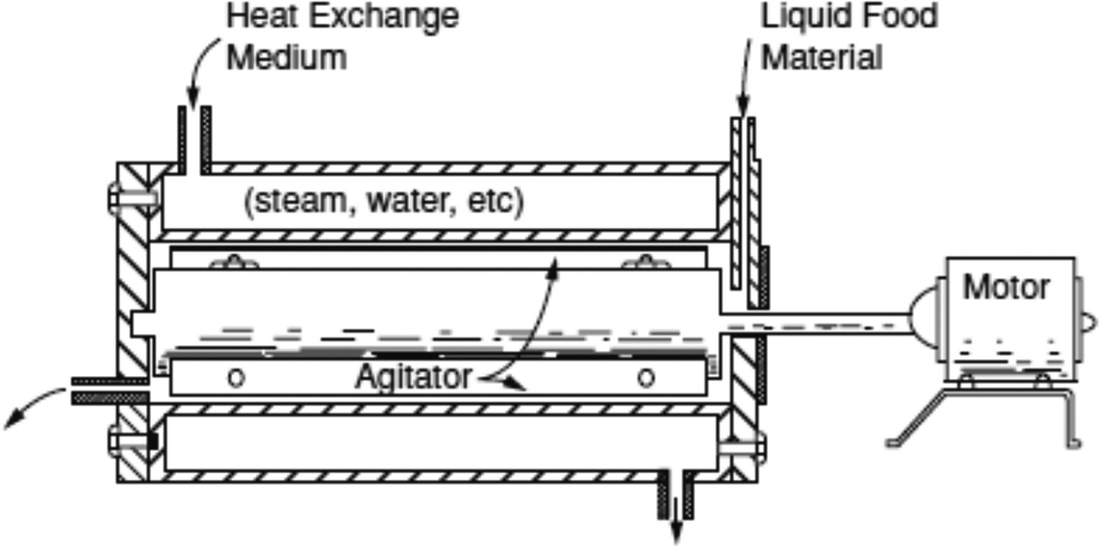

Safe efficient sterile. The energy released when steam condenses to water is in the range 2000 2250 kj kg depending on the pressure compared to water with 80 120 kj kg with temperature difference 20 30 o c. Change a product or fluid temperature. In case of cross flow heat exchanger measure the air velocity at the inlet to the blower with the help of a digital anemometer.

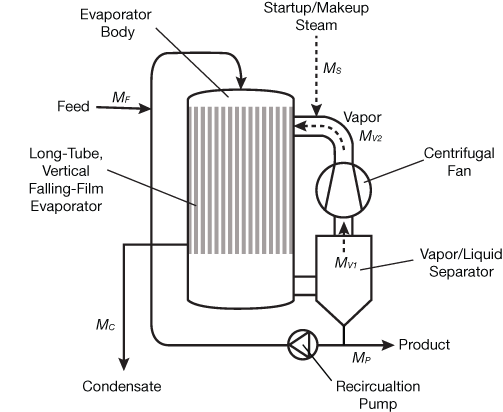

A shell and tube heat exchanger used to heat water for space heating using either steam or water is often referred to as a non storage calorifier. Showing 1 12 of 60 results. Heat transfer science definitions. The overall heat transfer coefficient u is related to the total thermal resistance and depends on the geometry of the problem.

Used in indirect heating applications. Type 2 pass diameter 4 in. For example heat transfer in a steam generator involves convection from the bulk of the reactor coolant to the steam generator inner tube surface conduction through the tube wall and convection boiling from the outer tube surface to the secondary side fluid. Computerized product selection helps you choose the heat exchanger that is just the right fit for your application requirements.

When an object is hot the molecules have a lot of energy and move fast. Note down the pressure of steam from pressure gauge on steam header. A storage calorifier as shown in figure 2 13 1 is constructed differently it usually consists of a hot water storage vessel with a primary heating coil inside. Taco u tube steam to liquid heat exchangers are designed constructed and tested to asme section viii div.

Heat energy is often called thermal energy. Working pressure 150 psi armstrong ws heat exchangers can be used in a broad array of industrial and commercial applications where fluids must be quickly heated or cooled.