Steel Grit Blasting Consumption

Steel grit and shot have one of the lowest breakdown rates of all blast media and can therefore be recycled and reused.

Steel grit blasting consumption. A abrasive consumption b delivered cost of abrasive c disposal of abrasive d labor cost e equipment cost x blasting speed in square foot hour or square meter hour understanding the many dimensions in which your abrasive affects your total cost is critical in properly submitting a profitable bid. Steel grit and shot are generally available with diameters of 0 007 0 078 in. Steel grit blasting abrasive is a durable long lasting abrasive blasting media that can be recycled many times in wheel shot blast machines wheelabrator machines manual autonomous robotic abrasive blasting rooms. Steel grit 10 325 230 8 0 low high 200 med.

Provide large air lines from the compressor to the blast machine. Cheaper is always cheaper. Steel grit is angular in shape whereas shot is round. Steel grit and steel shot used surface cleaning surface preparation or granite cutting.

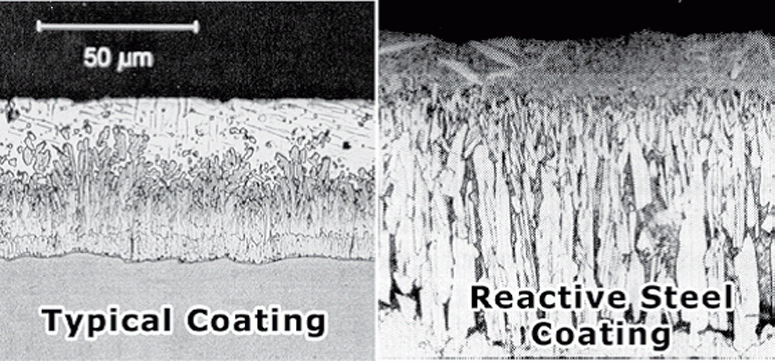

The angular nature of steel grit produces an etched surface on metal for superior. Steel grit is softer than aluminum oxide grit and does not fracture as easily. Understanding steel grit blasting abrasives offer a significant advantage to an industrial contractor s productivity and. Removing heavy scale steel shot 8 200 280 8 0 high 200 low mfd.

Steel grit will quickly strip many types of surface contaminants from steel and other foundry metals. X cookie management. Steel grit blast media is ideal for aggressive cleaning applications. Gl also loses its sharp edges during shot blasting and is particularly suited to descaling and surface preparation applications.

:quality(80)/images.vogel.de/vogelonline/bdb/1349000/1349001/original.jpg)