Steel Hat Channel Section Properties

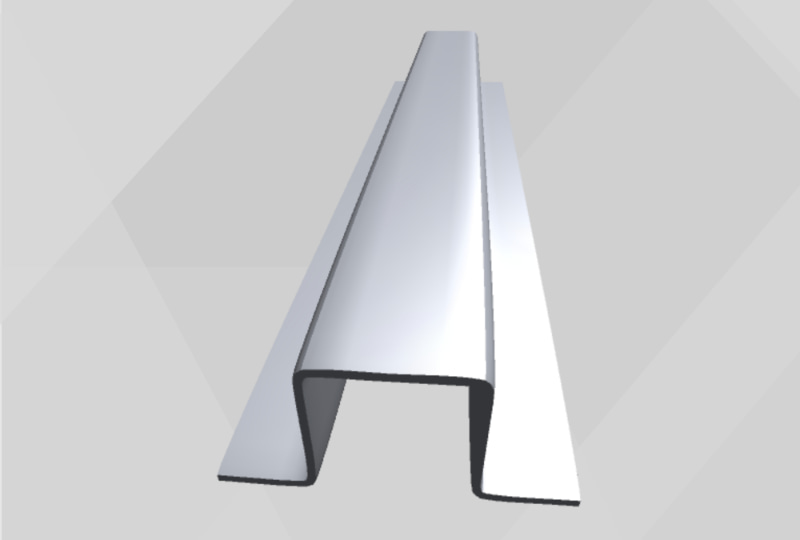

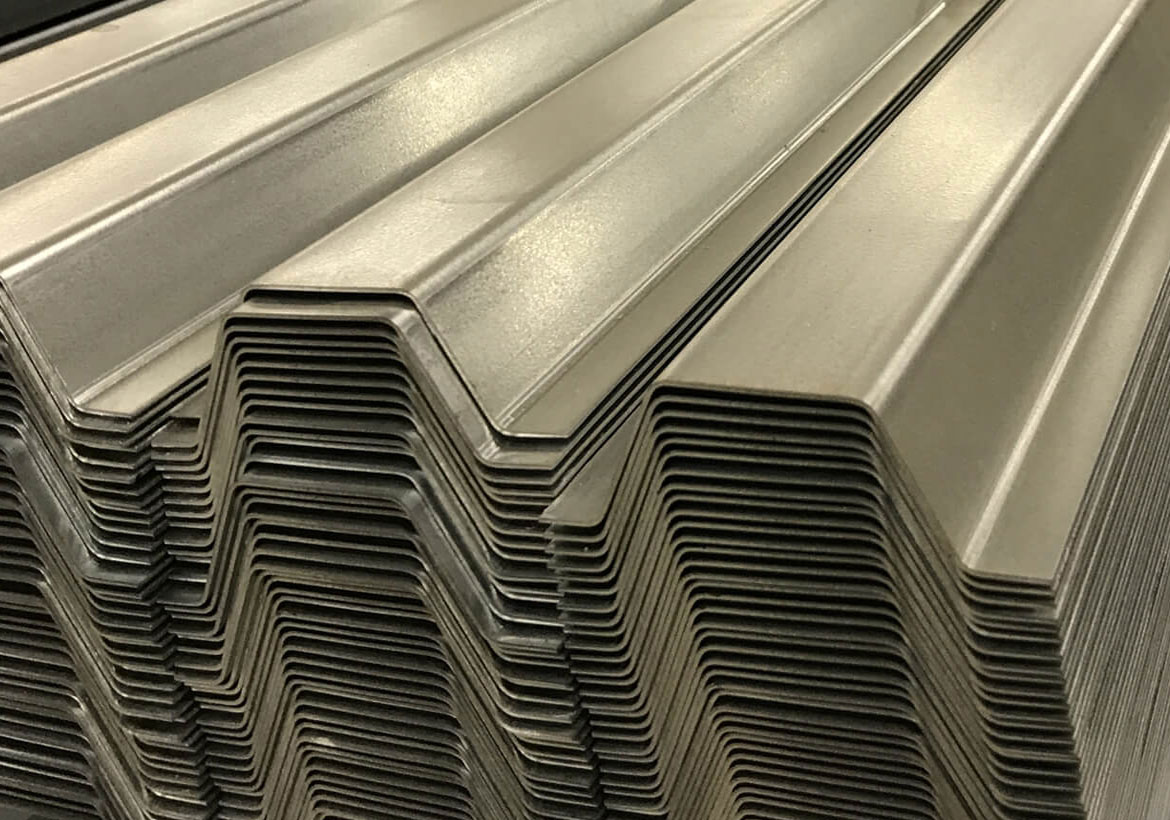

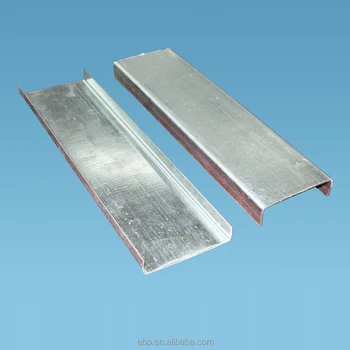

Cold formed top hat section.

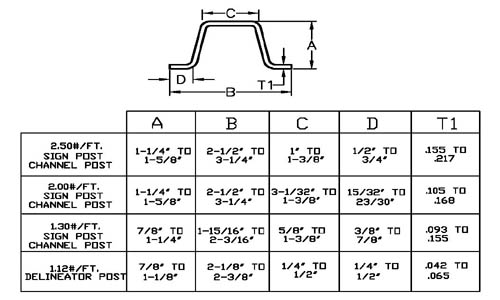

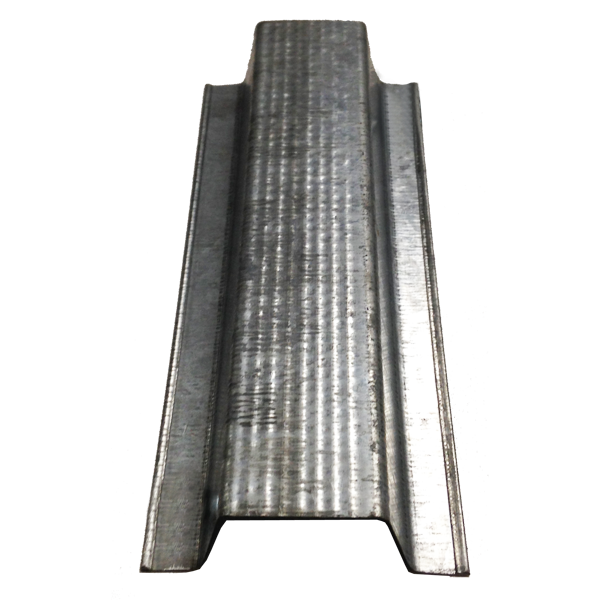

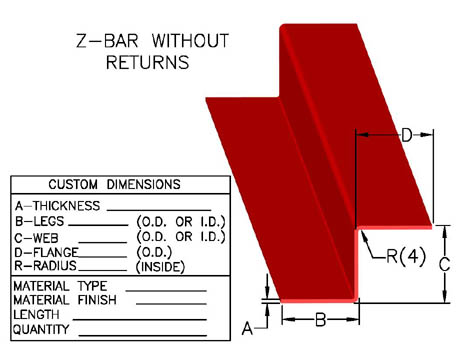

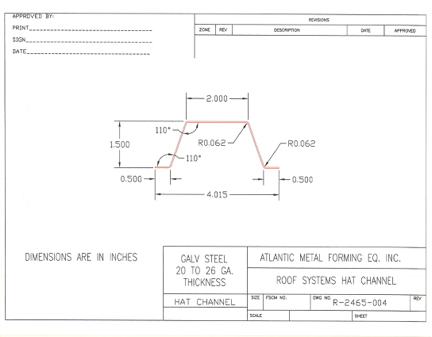

Steel hat channel section properties. Other lengths available hemmed leg furring channel as shown. While it is most commonly used in construction and transportation industries it is used in other applications as well. Example i 7 wall panel section with intermediate stiffeners 75. I 2 dimensions and properties for use with the 2001 north american cold formed steel specification.

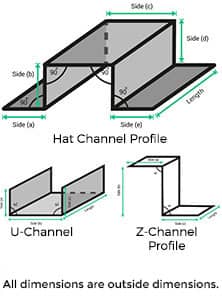

Top hat sections rolled from steel are widely accepted in the market. Example i 6 hat section without lips 71. Aptly named to reflect it s hat like appearance the hat channel is composed of two horizontal outward flanges the brim and two vertical. Effective ix is based on procedure 1 of naspec.

Each calculator is associated with web pageor on page equations for calculating the sectional properties. 3 5 effective section properties 78. 2 minimum base metal thickness is 95 of design thickness design thickness used for determination of properties. 1 calculated properties are based on aisi s100 12 north american specification for design of cold formed steel structural members.

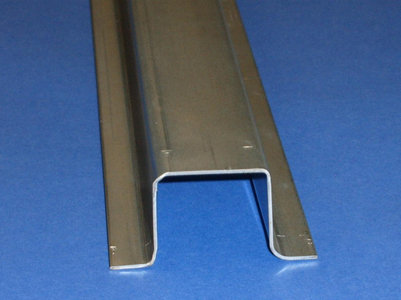

Materials hat channel section is fabricated from 25ti to 14 gauge hot dipped galvanized steel. Unlike similar u channels these gpo3 fiberglass hat channels have flanges for mounting to flat surfaces use them to route and insulate wire in humid environments. This profile is typically used in framing applications because of its corrosion resistance. Another popular open profile is a steel section named a top hat.

3 effective properties are based on fy 33ksi for deflection calculations use effective ix. 1 25 high x 2 5 wide hat channel in 18 gauge g90 galvanized steel. The links will open a new browser window. The web size is 1 1 4.

Hat channel s are fabricated in 1 2 7 8 1 1 2 depth from 25 gauge to 14 gauge steel. Dimensions the sides of the hat giving it the appearance similar to the side view of a top hat. Structural shapes properties resources. Astm code standards color code traditional 18 mil clear.

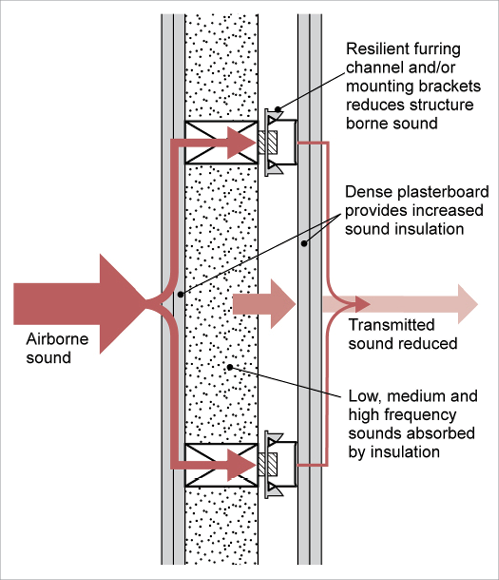

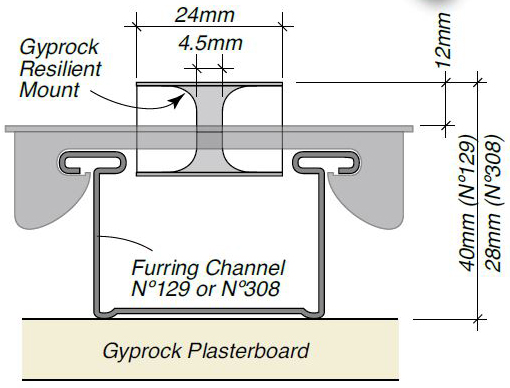

This tool is useful in the design process as a reference to determine the general availability engineering design data of specific structural steel shapes. Furring channel for walls and ceilings economical hat shaped framing component used to furr out ceilings and masonry walls. Made of fiberglass reinforced polyester they re often called polyester grade industrial laminate. All of these hat channels are arc and track resistant.

Special lengths are available. Hat channels get their name from their hat like shape. Length 12 0 and 20 0. They also have better electrical insulation properties than frp fiberglass.

The following links are to calculators which will calculate the section area moment of inertia properties of common shapes. Has been roll forming hat channels in all metals since 1948.