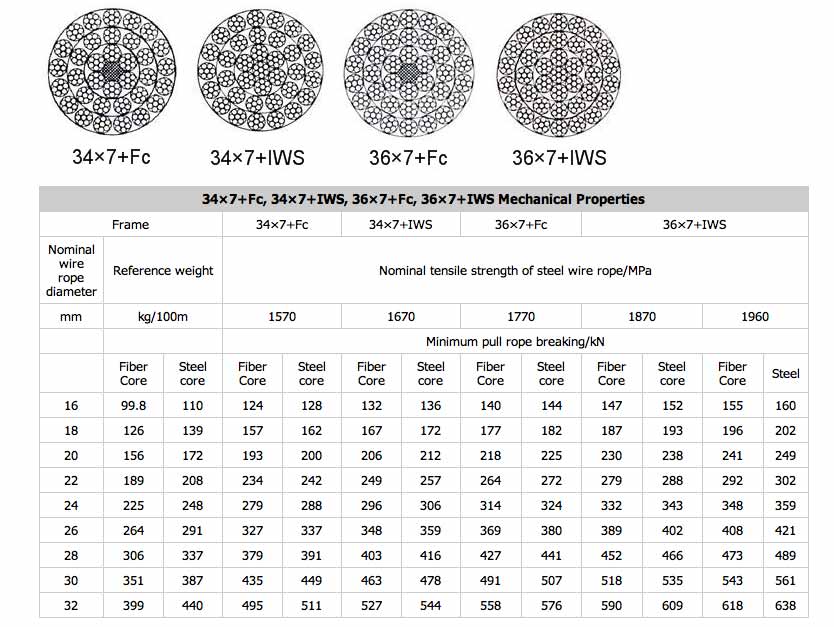

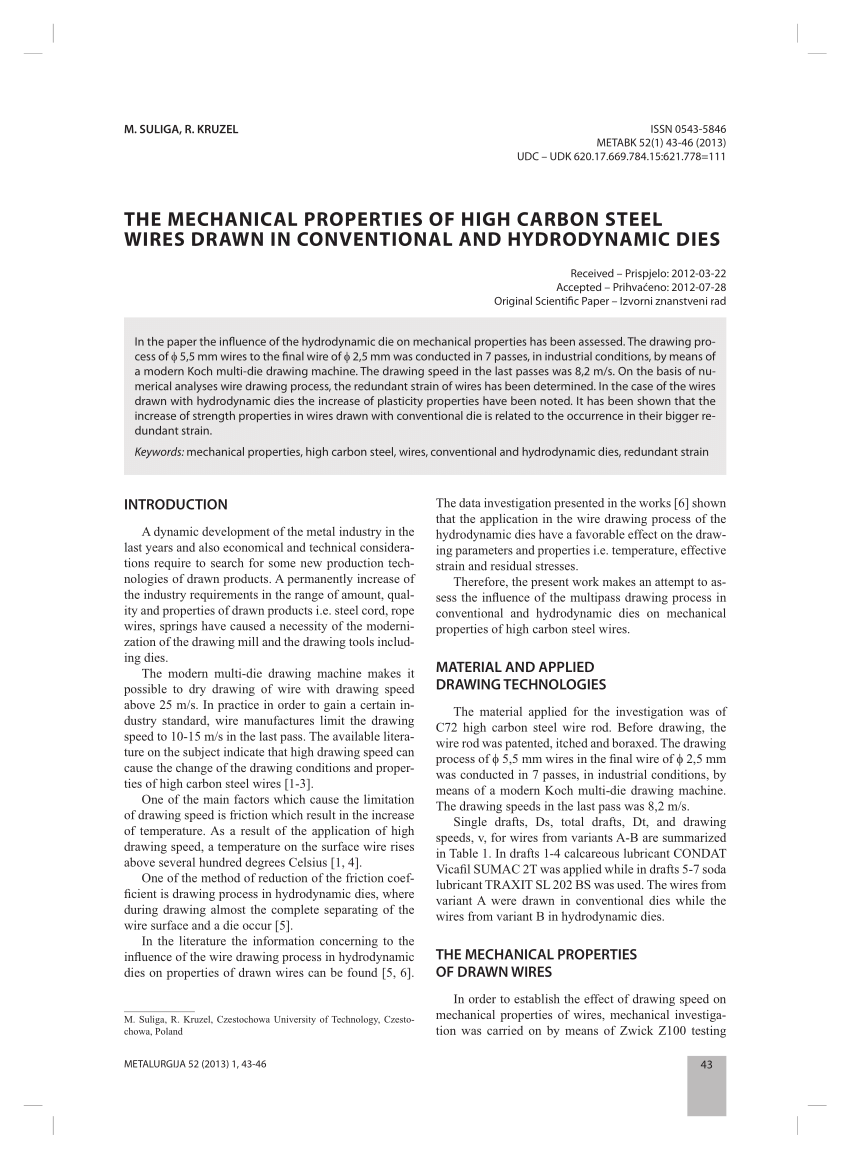

Steel Wire Tensile Strength Range

If you require different please ask.

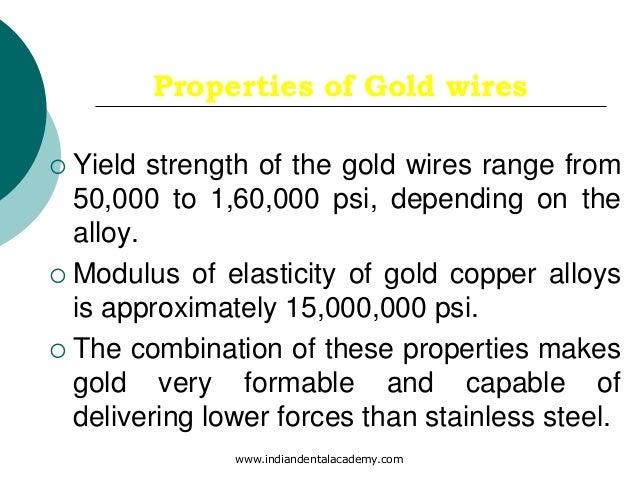

Steel wire tensile strength range. Ies 888 or any other international standard. Usually the carbon steel wires of high strength steel strand cold drawn wire of low carbon steel are used only in prestressed concrete structures. Stainless steel 304 like 302 has good mechanical properties and corrosion resistance. As noted in an ak steel data sheet on 304 stainless steel the alloy reaches its melting point at the 2 550 f 2 650 f 1399 c 1454 c range.

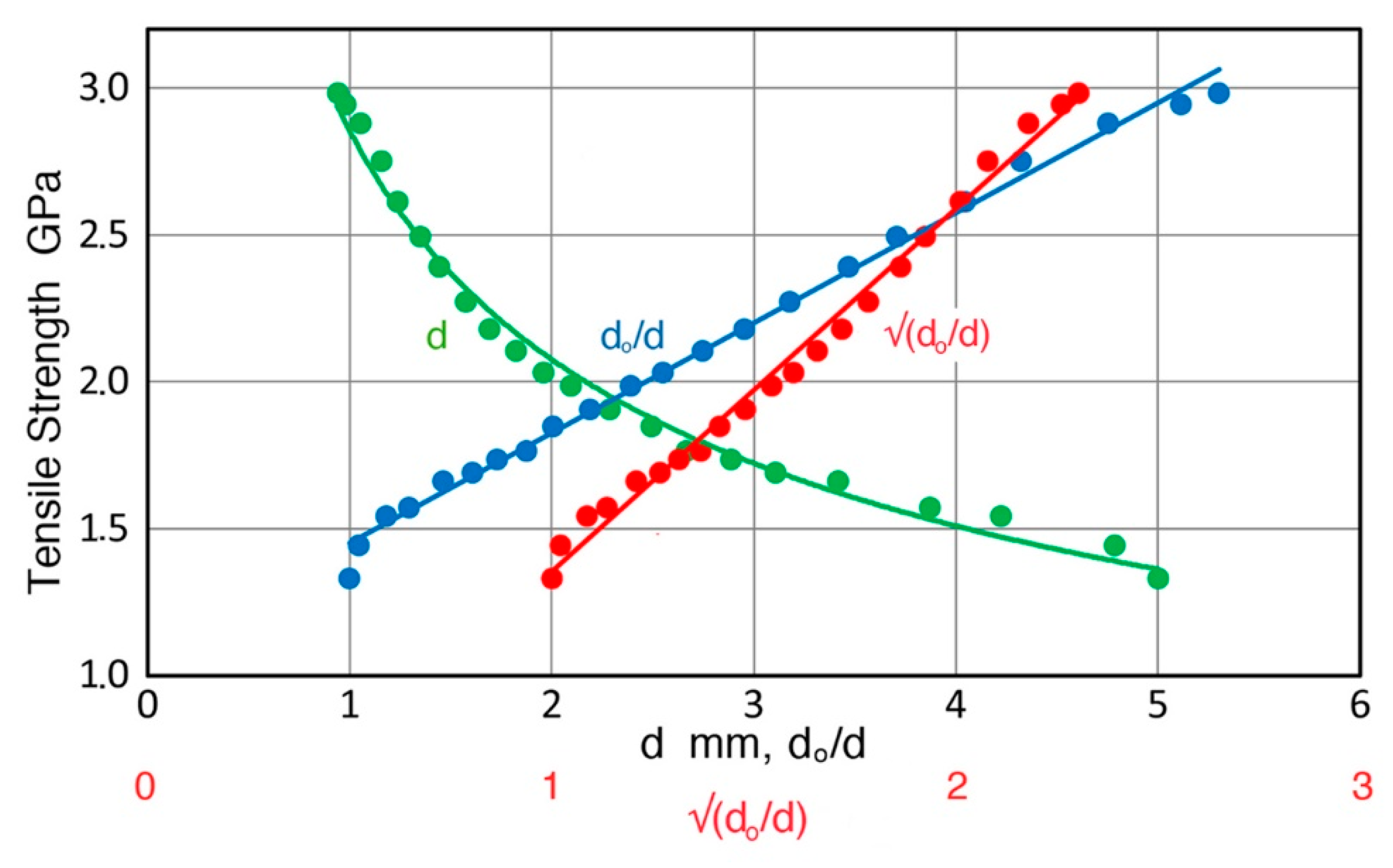

Electro hydraulic steel wire test machine performs perfect tension stest for the steel strand 7 wire strand for the reinforcement and prestressing of concrete wire rod and wires. Aluminum conductor steel reinforcement acsr wire. Diameter range 1 6mm to 5mm. Low or high carbon steel wire.

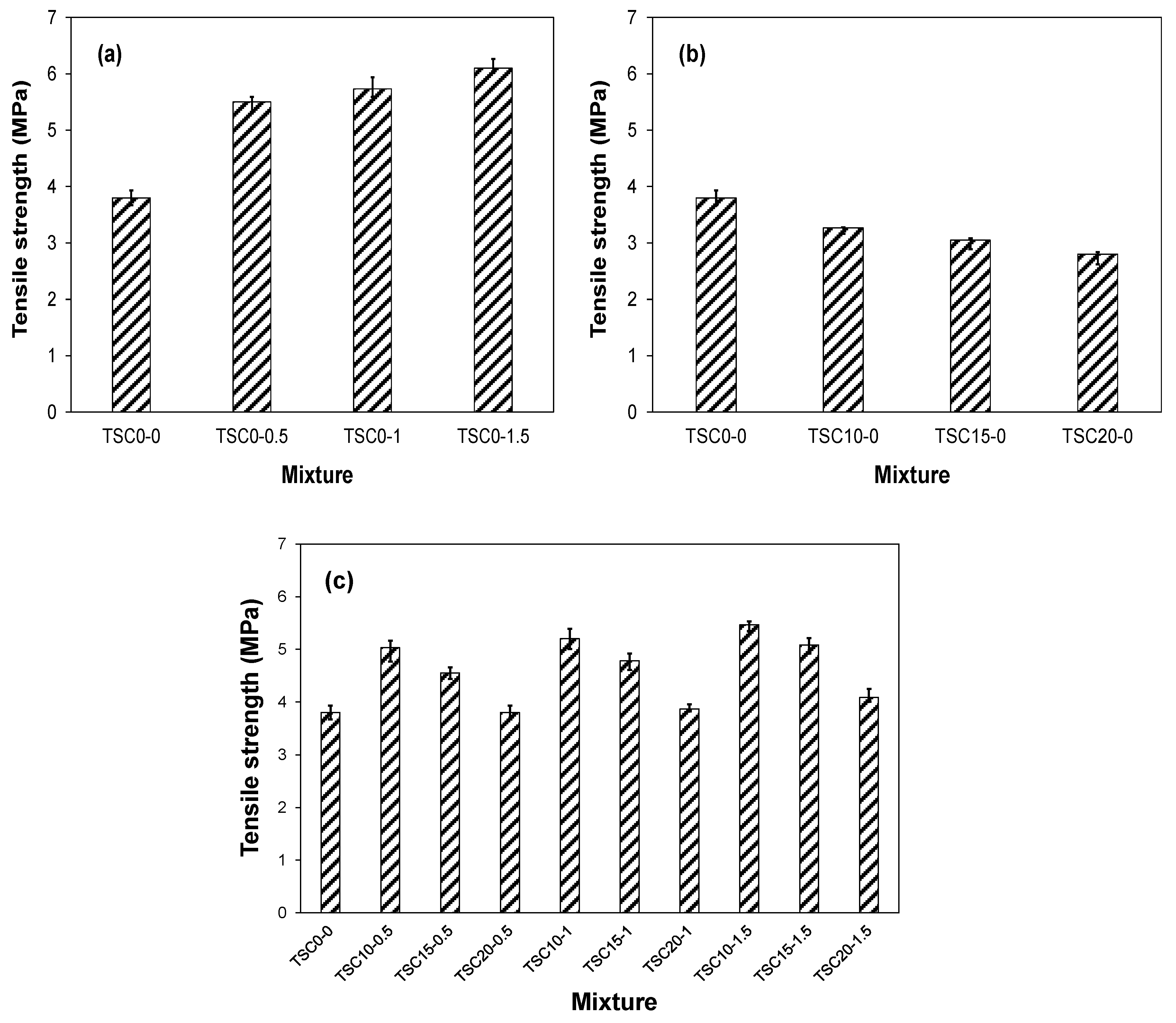

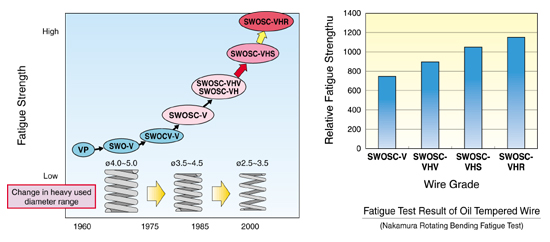

Zhenhai guo in principles of reinforced concrete 2014. And general test software to give an accurate determination of metal the material tensile strength. Infrabuild wire manufactures a wide range of spring wires for a multitude of applications. Yield strength tensile strength and ductility values for steels at room temperature.

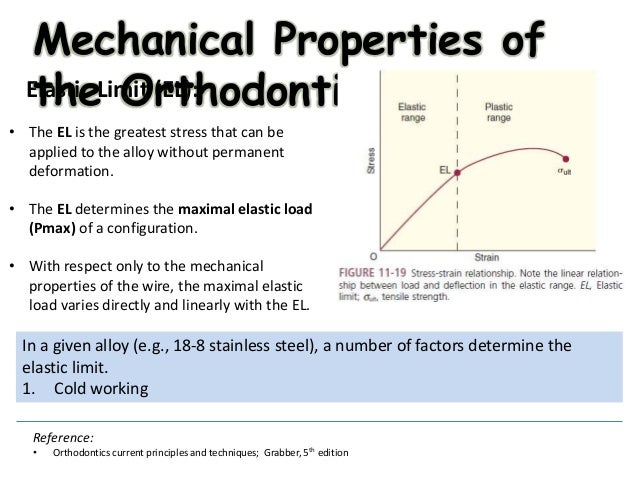

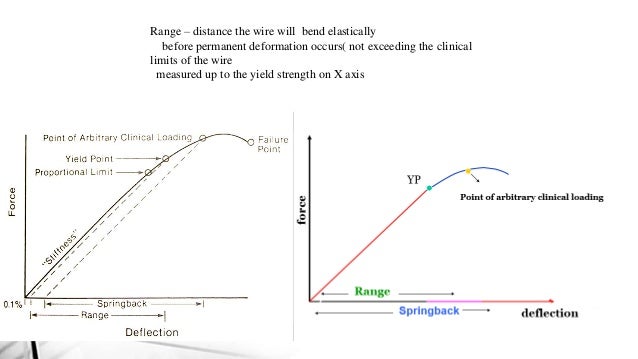

A wire with low tensile strength will break under a lesser load than a wire with high tensile strength. 11 5 4 reinforcement without yielding plateau. Stainless steel 304 like 302 has good mechanical properties and corrosion resistance. Mpa ksi mpa ksi steel alloy a36 hot rolled.

6 7 and the nominal yield strength of them f 0 2. The majority of products are made to conform to as1472 carbon steel spring wire for mechanical springs but may also be produced to comply with overseas standards or customer specifications typical applications include use in the automotive industry wire brushes trampolines. Wide range of applicable peripheral speeds and powers. Immediately you can understand why this is important.

Tensile strength elong. 210 30 min 380 55 min 25 min steel alloy 1020 cold drawn. In brittle materials the ultimate tensile strength is close to the yield point whereas in ductile materials the ultimate tensile strength can be higher. Astm b 498 93 bs en 50189 bs 4565.

Ultimate tensile strength uts often shortened to tensile strength ts ultimate strength or within equations is the maximum stress that a material can withstand while being stretched or pulled before breaking. 220 250 32 36 400 500 58 72 5 23. Naturally the closer the steel is to its melting point the more tensile strength it loses. After all if you are using wire for something like baling a load you need to know that the wire can hold up to the pressure it will be facing.

Steel alloy 1020 hot rolled. Contact a marlin steel mechanical engineer expert for your next 304 stainless steel project. The above tensile strength ranges are typical.