Water Based Adhesive Manufacturing Process

Adhesive manufacturing water based solvent based and acrylic based project report manufacturing process cost investment required.

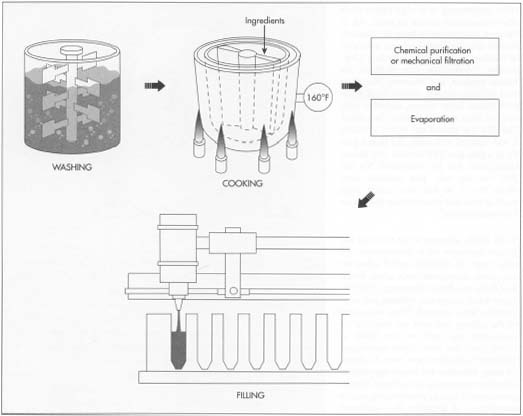

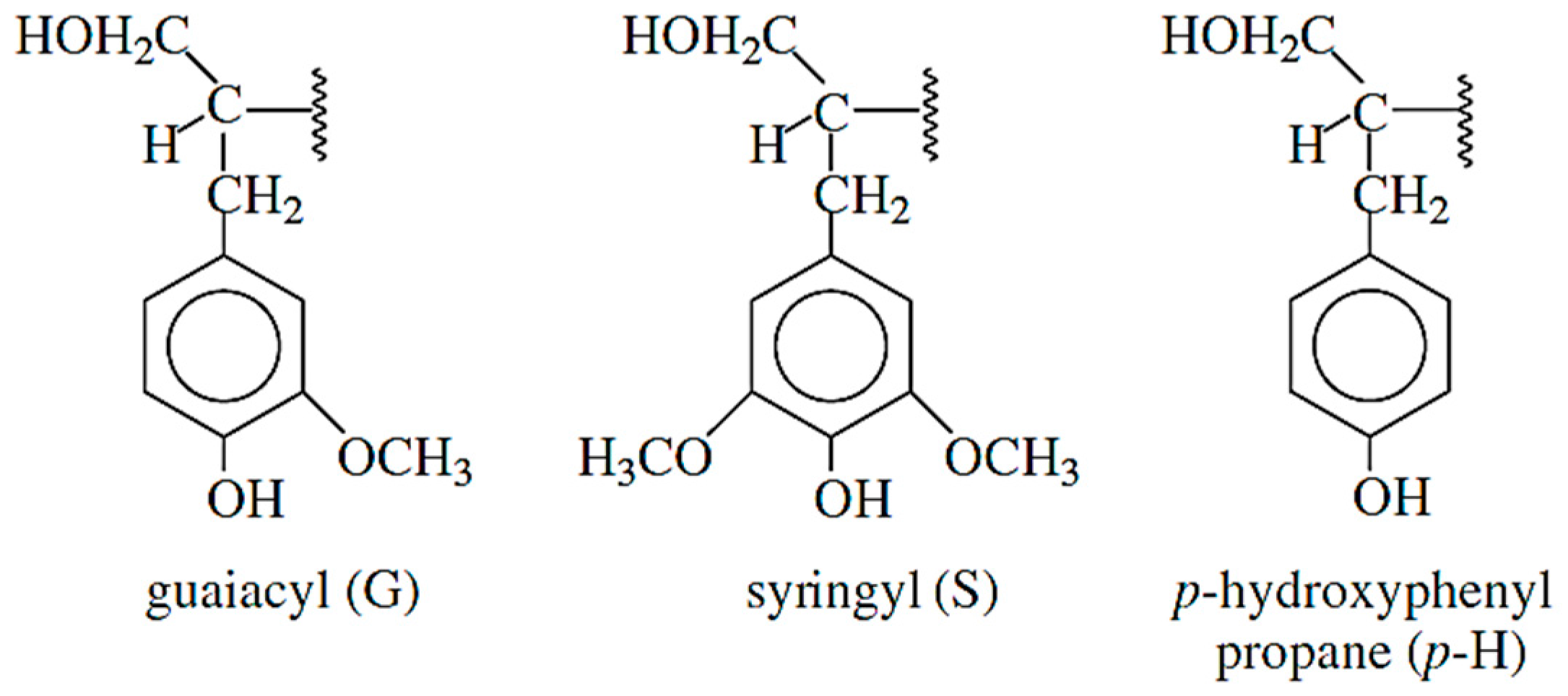

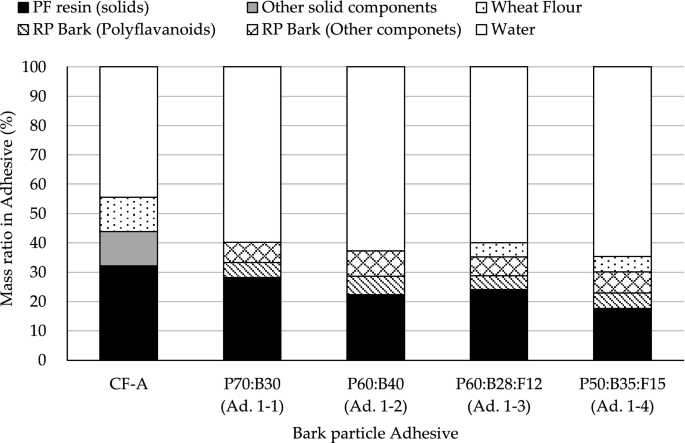

Water based adhesive manufacturing process. Environmental damage all stages of the manufacturing and application process for solvent based adhesives including formulation drying and curing release volatile organic compounds vocs into the atmosphere. Lignin adhesives introduction formulations 19. The use of advanced thermal joining processes such as ultrasonic welding. Adhesive also known as glue cement mucilage or paste is any non metallic substance applied to one or both surfaces of two separate items that binds them together and resists their separation.

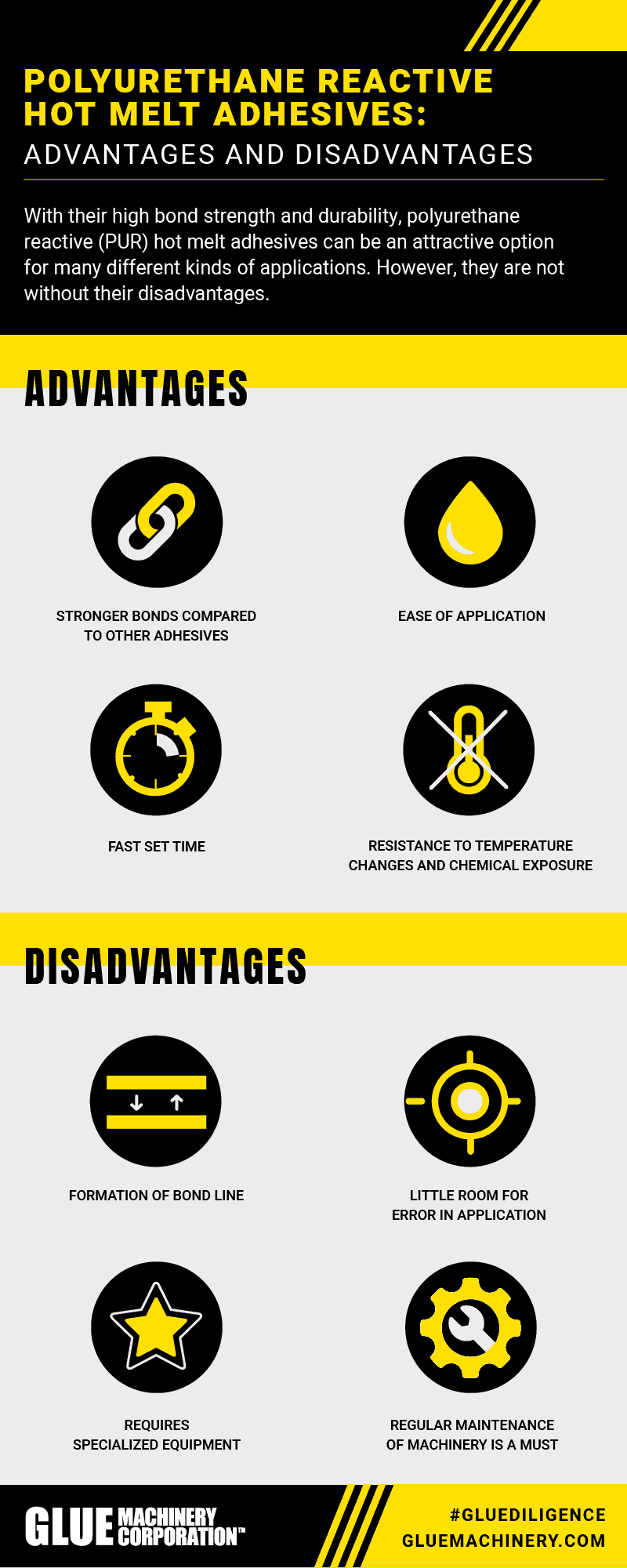

Cost solvent based adhesives are more expensive than water based adhesives. Manufacturing process of adhesives glues and resins glues of animal origin fish glues animal glues. Water based or more commonly referred to as waterborne adhesives are typically formulated from either. Typically when this adhesive is applied at a temperature around 110 130 c there is approximately one gram of water being absorbed by 100 grams of pur in the curing process in order to achieve full cure.

These pre polymers are thermoplastic and can be processed with gravure rollers in the screen printing process or with slot nozzles. Henkel s aquence is the brand for innovative sustainable water based adhesive solutions that are used in various applications. The use of adhesives nonblocking hot melts and reactive b staged adhesives for offline coating and combining later in. Natural polymers from vegetable sources e g.

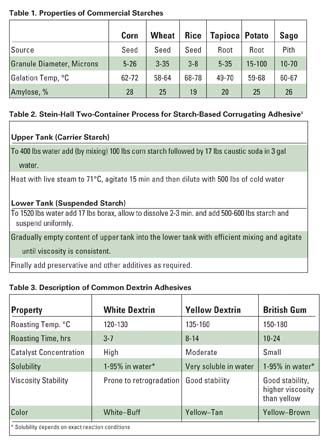

Report includes feasibility report profitability analysis raw materials break even points formulations and formula and much more. Polyvinyl alcohol cellulose ethers methylcellulose. Dextrins starches protein sources e g. These atmospheric pollutants are linked to a number.

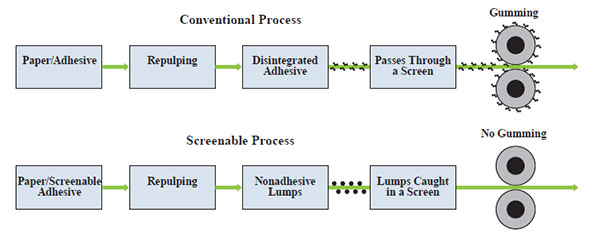

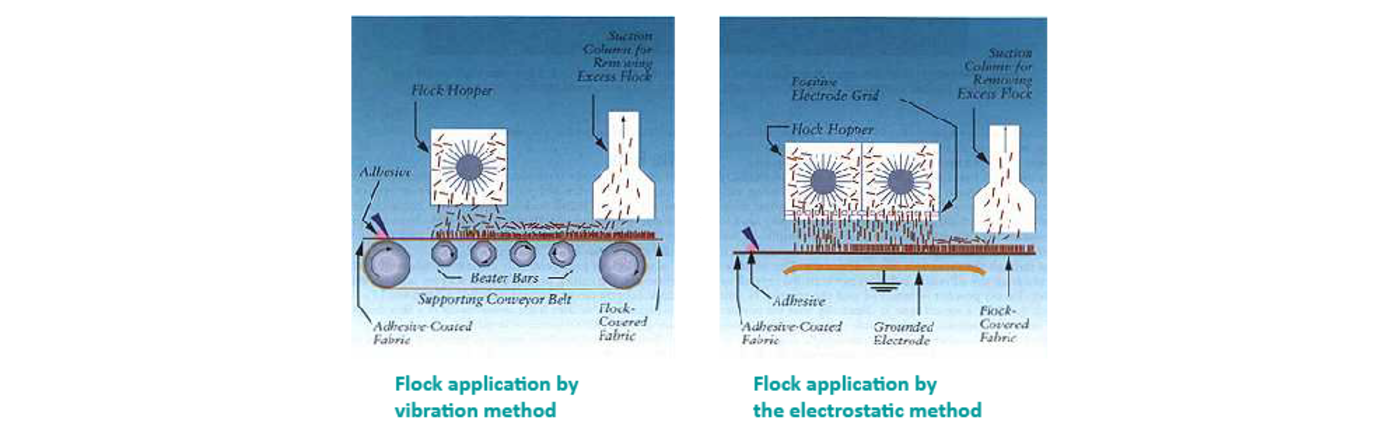

In addition to the move toward water based adhesive products and away from solvent types several trends have been noticeable in the textile industry over the past decade. The adhesives are coater ready and provide advanced bonding necessary to meet demanding applications in a wide variety of end use markets. Eco adhesives because of safety and environmental concerns regarding some synthetic glue manufacturing and application processes the adhesive industry is seeing a trend toward so called. Types and uses of isocyanate based adhesive system 18.

Casein blood fish soybean milk albumen and animal e g. The most common polymer based adhesives made from rubber include polychoropene styrene polyisobutylene polysulfide polyamide silicone and polyurethane.